After having seen the state of my LH quarter and its surroundings I knew I could expect the RH side to be similarly crap. Although not very visible, if you don't look you will never know and I really really really don't want to drive around later in a great looking car having doubts about the state of sheet metal here and there. So it was time to dig in!

I started at the rear drilling out the spot welds that connect the quarter to the taillight panel:

Make very sure you mark your reference spots well! I used the point above the bumper indent for the width and the side marker for the height:

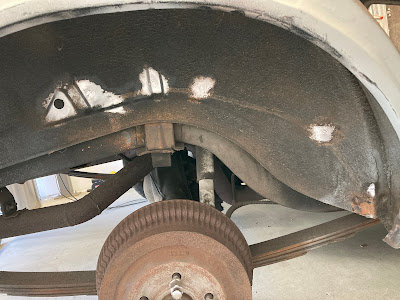

Then it gets serious. You gotta be careful when cutting around the wheel well because there is a support structure sitting on top of the wheelhouse that you may not want to cut into. So take your time, look for it and make sure you cut right. And indeed, I found a LOT of rust that needed to go:

So I bought this new outer wheel well a while ago and now it was time to cut out a patch to replace the crappy rusted out edge. I do not want to remove the whole outer wheel well, too much work I think plus, you have to deal with that support structure that sits on top of it again:

After a weekend of welding the wheel well has a new rust-free edge:

Next up: fixing the new quarter panel's drop-off. Like so many pieces of "new" sheet metal it's usually put together pretty poorly. I had to put some extra spot welds in and add a little to the edge that sits under the wheel well because it was too short:

The rear where the quarter wraps around was a little too rusty. I did not want to grind everything away because it would remove to much good metal as well. So I used phosphoric acid to remove the rust. It worked like a charm:

OK, after test fitting about 30 times I was confident the new quarter was good and the body was prepped and ready. I attached it to the body with 2 rivets and a few clamps:

Then it was time to tag the patch in place. I put rivets in the same holes as before so the patch was in exactly the same position. I added these super duper welding clamps to maintain a 1mm gap (almost) everywhere:

I took real good care of keeping the gap 1mm and having the sheet aligned perfectly everywhere. It paid off with a lot less warping. When I had enough tags I cut the sheet underneath the rivets and removed them. Then you simply carry on with tagging:

My office for a weekend:

Then there are also lots of plug welds that need to be made. I don't like doing them and I'm nog great at them (which is probably why I don't like them...). The ones one the wheel well edge were the hardest and I had about 8 actually popping off which I had to re do:

And then it's done:

Thank god there are only 2 quarters to fix!

Before and after:

I'm glad this one is done now. Next up is replacing parts of the floor. Oh dear, wish me luck!

No comments:

Post a Comment